Special

CAS 30 - T815-7 6x6.1R

on the TATRA T815-7 6x6.1R chasses

The Aussie Wildfire 9•6 fire truck is designed to fight fires in the bush and forest vegetation in Australia.

CAS 30 – T815-7 6×6.1R Water Tender with its concept ranks among tank trucks for interventions with water or foam. It is a special vehicle designed to operate on roads, off metalled roads and in rough terrain, when fighting fires in the bush or forest.

It is built on the three-axle chassis TATRA T815-732R33 having a wheelbase of 4090 mm + 1660 mm and engageable front axle drive. Single wheels are fitted on both the front axle and the rear axles. The crew cabin allows the transport of a three-member crew.

The fire truck is equipped with a centrifugal pump, tanks for water and foam concentrate.

The bodywork comprises the driver’s cabin (integral part of the chassis) and the purpose-built superstructure divided into:

– front platform for two fire-fighters,

– tank for water and foam concentrate,

– rear compartment for fire accessories and pumping equipment.

The driver’s cabin

The driver’s cabin is all-metal, two-door, tiltable cabin with flat windscreens. In the cabin there is the driver’s seat and two co-driver’s seats, all seats are equipped with inertia-reel three-point safety belts. Two map reading lamps are located in front of the dashboard. Light bar with blue and red lights and the siren with tone selection ("WAIL", "YELP", "HI-LO") and the loud-speaker for public address is located on the driver’s cabin. The light bar control box is located on the dashboard in the driver’s cabin.

In the cabin there are internal protective roller blinds placed above the windscreen and the side windows. When unrolled, they form a barrier to eliminate radiant heat emitted by fire.

Purpose-built superstructure

Between the driver’s cabin and the water tank there is the front platform (footbridge) where two fire-fighters are able to work also while the vehicle is moving. The platform frame is made of aluminium profiles screwed together and covered with aluminium plate bonded to the frame. The platform is accessible from both sides of the vehicle using the steps with handrail. Entrance to the platform is closed by the door with spring hinges which hold the door in the closed position. For safety reasons, the door opens inwards, thus preventing the fire-fighters from falling out.

In the front part of the footbridge, there is the special roller blind which can be used to shield the space for two fire-fighters to protect them from radiant heat from fire. On the platform there are two nozzles with DN 25 hose, 2 m long, and shut-off ball valves. Maximum delivery pressure is 16 bar. Platform monitors are installed on the left and the right side of the platform.

Tank for water and foam concentrate

The water tank is fabricated from stainless plates. Its shape is prismatic. The tank is fitted with a device for remote control of water volume. On the top side there is a manhole (diameter 510 mm) with hinged cover. Integrated water tank for self-protection system is a part of the water tank. The tank is designed so that it is refilled each time when the water tank is being refilled. The piping for interconnection with the water tank is in the bottom part of the tank and it is equipped with remote controlled shut-off flap by means of which the self-protection tank content can be discharged into the water tank when necessary.

In the rear part of the water tank there is the chamber of the auxiliary water tank which is used to increase the water tank capacity. The auxiliary water tank can be used only when operating off the public roads.

The water tank level indicator is located on the control panel on the front platform, in driver’s cabin and on the main panel in the rear left cabinet.

The foam concentrate tanks are fabricated from stainless plates and integrated into the water tank. They are fitted with the filler openings, the diaphragm bleeder valve with overflow and the device for remote control of foam concentrate volume.

The foam concentrate tank level indicators are located on the control panel in the driver’s cabin and on the main panel in the rear left cabinet.

Rear compartment for fire accessories and pumping equipment

The rear compartment frame is made of aluminium profiles screwed together and covered with aluminium plates bonded to the frame. The rear cabinet and the side cabinets are closed with aluminium roller shutters. The rear roller shutter covers the cabinet with the pumping equipment, the right and the left side cabinet houses the hose reel. The pumping equipment control panel is located in the rear left cabinet. The warning alley is located above the rear roller shutter, the warning beacons and the LED light are on the top platform. The reversing camera is installed in the upper part.

Pumping equipment

The pumping equipment is installed in the rear compartment. It consists of the centrifugal pump, suction and discharging piping with check valves. The pump control panel is located in the rear left cabinet below the hose reel.

Pump

The pump can be used for low pressure, high pressure and/or combined operation.

Primer is used for priming the pump and it can be operated in automatic mode (it is disengaged automatically after the pressure of 0.08 MPa is achieved in the pump). The primer can be also disengaged permanently (e.g. if the pressure fluctuates during operation and the primer engages intermittently).

Foam proportioning system

The foam proportioning system consists of jet foam inductor, control flap, electronic foam proportioning unit, two control panels and connecting pipeline.

Electronic foam proportioning unit

The vehicle is equipped with a universal system of automatic foam proportioning.

The principle function of the control unit is the regulation of foam concentrate and water proportioning by way of water and admixed agent flow rate measuring and by subsequent continuous proportioning within the range of 0 – 6 % with 0.1 accuracy.

Two values of the proportioning ratio may be stored in the memory for a fast selection. The adjusted proportioning percentage is maintained automatically and independently from the actual flow rate at the pump outlet.

Equipment for rapid fire-fighting intervention

The high-pressure equipment for rapid fire-fighting intervention consists of the pumping equipment high-pressure system and the hose reels located in the rear left and the rear right cabinet.

The high-pressure equipment can be operated also in low-pressure mode.

The rapid intervention equipment is permanently connected to the pumping equipment. It consists of the through-flow hose reel, delivery hose DN 25 (60 m long) and gun-type nozzle allowing to control the flow rate and discharge cone (stream pattern).

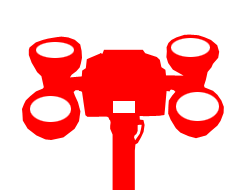

Bumper monitor

The bumper monitor is located in front of the front bumper. The bumper monitor can rotate in both the horizontal and the vertical direction and allows the nozzle spray pattern to be adjusted from straight jet to wide fog.

The bumper monitor can be operated from the control panel located in the driver’s cabin. Monitor travel is controlled by pushing the joystick to the desired stream direction.

You can control the water supply in two ways:

- by means of the button on the joystick,

- by switching on the ball valve switch on the control panel.

The spray pattern of the bumper monitor nozzle is controlled using the rocker switch on the top of the monitor joystick.

The bumper monitor is designed for use with both water and foam.

Self-protection system

The vehicle is equipped with the self-protection system protecting the vehicle and the crew from the radiant heat from fire. The system comprises 700 litre water tank which is sufficient for 5 minute operation of the system at engine idle. The pressurized water is distributed through the piping from the pump to the protective nozzles which are located on the vehicle exterior so that they protect the driver’s cabin, the platform with the operators, the roof and the vehicle underside including the tyres and suspension air bellows.

It can be used with or without foam.

The self-protection system is equipped with backup electric pump producing 70 lpm at 1.0 bar. The backup pump system is controlled by the safety button on the in-cabin control panel. During operation of the backup electric pump only the nozzles on the roof of the driver’s cabin are active. Foam concentrate cannot be admixed to the self-protection system in this mode.

Cable winch

The electric cable winch (50.7 kN pulling force) with protection against overloading is fitted on the front part of the chassis. The winch is connected to the hitch in the front bumper and it is removable.

Technical data

Vehicle dimensions | |

| Length | 9 440 mm |

| Width | 2 500 mm |

| Height at curb weight | 2 780 mm |

| Ground clearance below axle | 360 mm |

Vehicle weights | |

| Operating weight | 14 700 kg |

| Gross vehicle weight | 24 000 kg |

CHASSIS

| Type | TATRA T815-732R33 6x6.1R |

| Engine type | Diesel, supercharged, air-cooled, direct fuel injection engine |

| Engine output | 325 kW/1 800 min-1 |

| The engine complies with emission standard EURO 5. | |

| Drive | 6x6 with engageable front axle drive |

| Gearbox | six-speed, fully automatic gearbox with hydrodynamic torque converter |

| Brake system | four independent systems, ABS |

| Electrical system voltage | 24 V (two batteries of 12 V / 170 Ah) |

| Fuel tank capacity | (Diesel / AdBlue) 320 l / 67 l |

| Maximum vehicle speed | 100 km/h |

CAB

| Type | single-compartment, two-door, tilt cab |

| Number of seats | 1 + 2 |

SUPERSTRUCTURE

| Material | frame made of aluminium profiles and covered with aluminium plates glued-on |

TANKS

| Main water tank | 6 600 l |

| Auxiliary water tank | 1 500 l |

| Self-protection tank | 700 l |

| Foam concentrate tank | 2x 100 l |

PUMPING EQUIPMENT

Low-pressure system | |

| Rated water flow rate | 3 000 l/min |

| Rated working pressure | 1.0 MPa |

| Rated suction lift | 3.0 m |

High-pressure system | |

| Rated water flow rate | 400 l/min |

| Rated working pressure | 4.0 MPa |

HOSE REEL

| Hose dimensions | DN 25/60 m |

| Branchpipe | Jet Protek 360 |

| Selectable flow rate | 19 - 37 - 90 - 150 l/min |

| Rated pressure | 4.0 MPa |

PLATFORM MONITORS

| Monitor type | POK Snake |

| Nozzle type | Jet Protek 366 |

PLATFORM HAND GUNS

| Nozzle type | Jet Protek 360 (high-pressure) |

| Hose type | Elaflex TW25 |

BUMPER MONITOR

| Monitor type | Sidewinder 8494-01 |

| Control type | remote |

SELF-PROTECTION SYSTEM

| Pump type | Sigmet ECC24/40 |

| Nozzle type | PLH 7,5, Sprinkler Minimax, MX-FU |

CABLE WINCH

| Winch type | Ramsey electric |

| Pulling force | 50.7 kN |

Ask us!

Would you like to be informed about the details of this car? Write to us and we will get back to you.

Hotline - repairs, service

Hotline - repairs, service